THE 31st annual Hillside Community Festival at Guelph Lake Conservation Area in Ontario made a notable addition to its clean-up crew this year. After 10 years of dreaming up plans, a small team of volunteers led by Nick Dalton of Magda Farm constructed a solar-powered water-heating system for dishwashing that will continue to reduce the three-day festival’s energy use for many years to come.

THE 31st annual Hillside Community Festival at Guelph Lake Conservation Area in Ontario made a notable addition to its clean-up crew this year. After 10 years of dreaming up plans, a small team of volunteers led by Nick Dalton of Magda Farm constructed a solar-powered water-heating system for dishwashing that will continue to reduce the three-day festival’s energy use for many years to come.

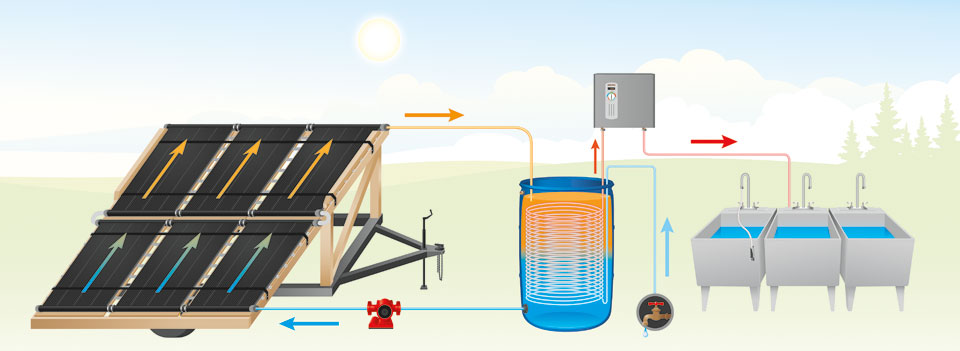

The system was built on top of a camper trailer frame that had been abandoned years ago at the site, using a combination of off-the-shelf components and homegrown ingenuity. Hillside wants to encourage other festivals to prioritize sustainability as a core value by sharing construction details of the project.

Solar panel array

The system has six solar panels, each measuring four by eight feet, manufactured by TechnoSolis (Model #C20TS08 – technosolis.com). Each panel costs around $330, plus about $50 in hardware fittings per panel.

The panel construction is similar to corrugated plastic board, with water channels running the full length of each unit and guiding the flow into end pipes. The bottom panels lift and stack on the top for storage.

The panels are at a 23º angle to maximize efficiency for the location and time of year.

The connection between the upper and lower panels (A) is a custom u-bend pipe made using off-the-shelf parts.

Adjoining panels are connected using a short section of flexible tubing and plumber’s clamps (B).

The panels are supported on plywood laid over steel pipes, held in place by nylon strapping (C). This loose attachment approach allows for thermal expansion of the panels, and thereby prevents warping.

Circulation pump

Hillside used a Grundfos 120 watt pump (Model #UP15-42F – ca.grundfos.com) to keep water moving through the system. The pump retails for approximately $130.

Water circulates through the system every five minutes. The solar-heated water exits from the top of the panel array, and the cooled water is pumped back into the bottom of the array.

The pipes connecting the pump, panel and rain barrel heat exchanger are 1/2-inch PEX pipes. PEX is commonly used for hot water applications and is made from high-density polyethylene (HDPE).

Heat exchanger

Water used for dishwashing is kept separate from the water used in the solar panels.

The heat exchanger is constructed using a standard 208L rain barrel ($25-50) and 150’ of 5/8” copper pipe ($1-$2 per foot).

The copper pipe is connected to the municipal water supply. Water enters the coil of copper pipe at the bottom of the barrel. As water spirals to the top, it absorbs the heat from the separate flow of water warmed by the solar panel array.

The solar-heated water enters the top of the rain barrel and exits through the bottom. The temperature gradient in the barrel is 25ºC at the top and 20ºC at the base. The water in the barrel naturally stratifies, keeping a constant supply of hot water near the top.

Tankless water heater

The water is raised to a final temperature of 42ºC using a standard domestic tankless water heater ($660, Stiebel Eltron Tempra Plus 20 –stiebel-eltron-usa.com).

Pre-heating the water using the solar panels reduced Hillside’s dishwater heating energy use by approximately 30 per cent while cleaning dishes from more than 9,500 meals served during the three-day festival. The solar panels used are for swimming pool water heating, so they’re not designed to operate at the higher temperatures necessary for dishwashing.

The philosophy behind the Hillside water “pre-heater” was to save energy and provide an example of a project that is simple enough to be deployed by other festivals and events.

Future Improvements

Hillside is planning upgrades to the system. Suggested improvements so far include building a greenhouse from polyethylene plastic around the panels to reduce heat loss, adding more panels and installing a flat-plate heat exchanger in addition to the barrel to improve heat transfer efficiency.

IMPORTANT NOTE

The relatively inexpensive plastic solar panels used in the construction were originally designed to heat swimming pools. These panels are appropriate for use only in continuous flow systems, as excessive heat build-up can damage the panels, causing them to potentially “balloon,” even under normal operating pressures. Within a continuous flow operation, the panels will stay cool enough to operate without issue.

This system design is not appropriate for year-round use, such as in a home water heating system. It must also be completely drained before storage in fall and winter to prevent damage from water freezing in the pipes and panels.

Research the professional resources who contributed to this project at magdafarm.blogspot.ca and guelphsolar.net.

4919

Nik has straddled the lines between graphic design, fine arts and scientific research for over 22 years. With a passion for image-making, pushing pixels and communicating complex ideas, his interest in the environment stems from his love of the landscape and a recognition of the profound changes that are impacting its natural beauty.